Silvio

Well-known member

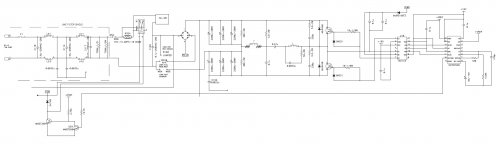

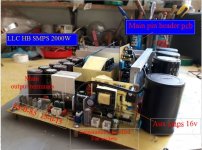

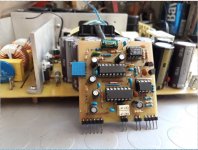

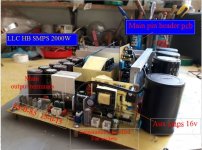

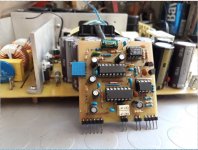

Here is an smps that I have been working on for the last 6 months. This is my first prototype and apart from the simplicity this smps has a lot of features for it to work on an audio amplifier.

1) Over input voltage protection with a Varistor

2) A good input filter to reduce EMI as much as possible

3) Generous input and output capacitance 2700uF in the 320v input and 10,000uF on the output

4) A good soft start design

5) A good short circuit protection which is self reset after 3 seconds and turns to hiccup mode if the short is still present. Eventually it will turn to thermal protection sensing the heat on the soft start resistors.

6) Thermal protection with a normally open bi-metal switch on the IGBT heat sink

7) Temperature controlled fan speed for 3 X 12v 80mm fans.

8) Being LLC has a sinusoidal current wave form. This helps a lot in reducing EMI and noise

9) From my initial tests it seems very promising and very strong.

10) The SMPS peaked 2300w with a modest voltage drop of 11% on the output voltage.

11) The power factor was 0.65 with no load and 0.98 at full load.

12) The efficiency reached around 89%

13) Lastly the fuse was omitted from the PCB as this is to be attached on the amp chassis.

1) Over input voltage protection with a Varistor

2) A good input filter to reduce EMI as much as possible

3) Generous input and output capacitance 2700uF in the 320v input and 10,000uF on the output

4) A good soft start design

5) A good short circuit protection which is self reset after 3 seconds and turns to hiccup mode if the short is still present. Eventually it will turn to thermal protection sensing the heat on the soft start resistors.

6) Thermal protection with a normally open bi-metal switch on the IGBT heat sink

7) Temperature controlled fan speed for 3 X 12v 80mm fans.

8) Being LLC has a sinusoidal current wave form. This helps a lot in reducing EMI and noise

9) From my initial tests it seems very promising and very strong.

10) The SMPS peaked 2300w with a modest voltage drop of 11% on the output voltage.

11) The power factor was 0.65 with no load and 0.98 at full load.

12) The efficiency reached around 89%

13) Lastly the fuse was omitted from the PCB as this is to be attached on the amp chassis.

Last edited: