zeus_threat

Member

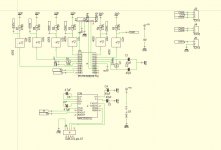

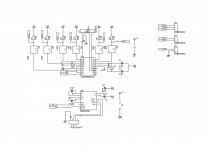

Being curious about logic analyzers and pc based oscilloscopes, I started researching a little bit. I had initially looked at the bitscope oscilloscope. The original bitscope based on 16F84 and then the BS300 which have their schematics published gave me some ideas. The solution is based on a hardware and pc based software combination. The hardware for a logic analyzer based on a buffer connected to a SRAM chip. The microcontroller controls the address when data is stored in the SRAM and then sends everything to a pc. There is a second non electronic and less DIY friendly which is the pc software. I have successfully obtained/built the following:-

1) CD4050 buffer- max 15V input

2) HM62256 32K x 8 bit RAM- Allows to create a 8 channel 32K buffer logic analyzer

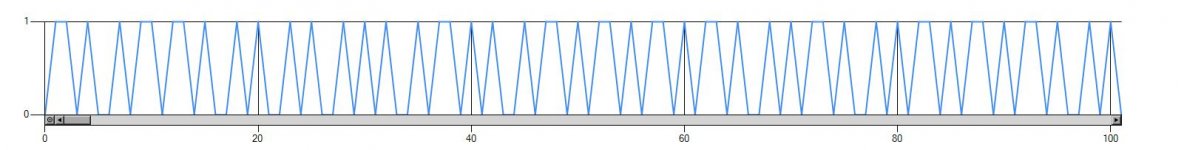

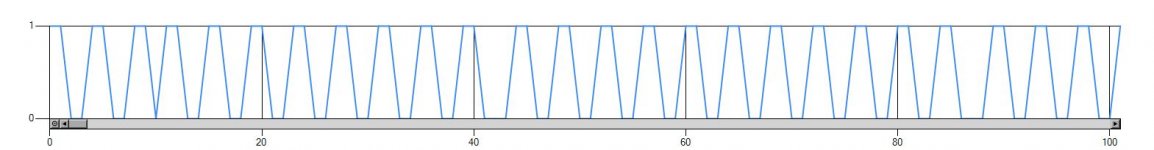

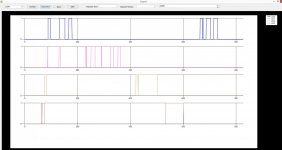

3) C#.NET based application using MSchartcontrol of type line with a max Y-Axis limit of 1 and low limit of zero that can read serial ports(I am using FTDI serial to USB conversion for the time being)

I need to fit all the above together but the software with a simple serial dump from the microcontroller worked.

Whats needed to turn the above into a pc based DSO is a TLC5540 75MHz bandwidth 8 bit ADC capable of 40MSps () in a combination with a vertical buffer connected to the CD4050 buffer, change the graph to match the vertical sensitivity.

All this does not seem impossible but I will keep it as a logic analyzer first and then consider the DSO.

The are simpler implementations like the DPscope which I consider to prototype and see what happends

I'll keep posted

1) CD4050 buffer- max 15V input

2) HM62256 32K x 8 bit RAM- Allows to create a 8 channel 32K buffer logic analyzer

3) C#.NET based application using MSchartcontrol of type line with a max Y-Axis limit of 1 and low limit of zero that can read serial ports(I am using FTDI serial to USB conversion for the time being)

I need to fit all the above together but the software with a simple serial dump from the microcontroller worked.

Whats needed to turn the above into a pc based DSO is a TLC5540 75MHz bandwidth 8 bit ADC capable of 40MSps () in a combination with a vertical buffer connected to the CD4050 buffer, change the graph to match the vertical sensitivity.

All this does not seem impossible but I will keep it as a logic analyzer first and then consider the DSO.

The are simpler implementations like the DPscope which I consider to prototype and see what happends

I'll keep posted

![Photo-0158[1].jpg](/forums/data/attachments/3/3770-58ab9a05dc18a10e770559a550f971c3.jpg)