Hi All

I have need help how to change a schematic who is only constant current source smps for welding.

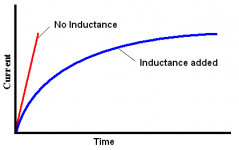

I have look some videos and hear that when use output capacitors there is a fase shift and so I need

a opamp to ivert it and outpu go to pwm chip V/feedback pin. The UC 3845 has such pin.

I have fount a schematic of a ordinary 3-60 volts 40 amp smps supply schematic who has both but this

is afcourse a very different use, I weld with it.

a resister voltage devider between smps output is used in video, then a inverter opamp (because it,s

output filter shift 180 degrees) the opamp has also a integrator on bord as error amplifier.

The UC3845 has a opamp build in who can be used so why some people use extern?

Maybe some here can make more clear how to do best make a welding mig smps inverter with constant

voltage, I do use the current feedback afcourse but then as protection agains overload.

thanks

kees

I have need help how to change a schematic who is only constant current source smps for welding.

I have look some videos and hear that when use output capacitors there is a fase shift and so I need

a opamp to ivert it and outpu go to pwm chip V/feedback pin. The UC 3845 has such pin.

I have fount a schematic of a ordinary 3-60 volts 40 amp smps supply schematic who has both but this

is afcourse a very different use, I weld with it.

a resister voltage devider between smps output is used in video, then a inverter opamp (because it,s

output filter shift 180 degrees) the opamp has also a integrator on bord as error amplifier.

The UC3845 has a opamp build in who can be used so why some people use extern?

Maybe some here can make more clear how to do best make a welding mig smps inverter with constant

voltage, I do use the current feedback afcourse but then as protection agains overload.

thanks

kees