ravs

In my opinion, You are complicating things for no reason.

If you are using ETD44 as indicated @70Khz @ 1200 Bmax

Primary turns is 26 Turns

for 50 - 0 - 50 VDC output you need 8 turns -0 - 8 turns

at least you need 1.2MM for Primary if you need 600W, strand many thin wires together, its known method, See ludo3232 how he did it.

Other wise I cant see any thing prvents that SMPS from working.

* where did you get the Vin Max 270v from?

Help is there always

Thanks

Hi Microsim,

I'm just wondering how to determine the estimated wire size in AWG. I've been studying book of marty brown and abraham pressman but it lacks answer in determining the wire size. I have the following calculation and I cannot start in contructing my transformer since I stop in determining the wire size. My project is a low voltage high current power supply using controller TL494.

My calculation:

1. Rated Output Power Po = (12Vdc) * (40Amps) = 480Watts

2. Estimated Input Power Pin = 480W/0.8 = 384Watts (for 80% efficiency)

3. DC input voltages (A voltage doubler will used for 110Vac)

a. From 110 Vac:

Vin(low) = 2(1.414)(90Vac) = 254 Vdc

Vin(high) = 2(1.414)(130Vac)= 368 Vdc

b. From 220 Vac:

Vin(low) = (1.414)(185Vac) = 262Vdc

Vin(high)= (1.414)(240Vac) = 339Vdc

4. Average Input Currents (DC)

a. Highest Average: Iin(max) = 384W/254Vdc = 1.51A

b. Lowest Average: Iin(min) = 384W/339Vdc = 1.13A

5. Estimated maximum peak Current Ipk = 2.8(480W)/254Vdc = 5.29A

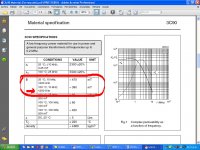

Ae=107mm^2 = 1.07cm^2 for ER35

Controller frequency = 80Khz

Bmax = 1500

NPRI = (Vin(max) * 10 ^ 8) / (4 * F * Bmax * Ac)

NPRI = (169.5 * 10 ^ 8) / (4 * 40000 * 1500 * 1.07)

NPRI = 66,100 ~ 66 turns

Vfwd = output diode forward voltage

Nsec = (1.1 * (Vout + Vfwd) * NPRI) / (Vin (min) * DCmax)

Nsec = (1.1 * (12 + 0.5) * 66) / (127 * 0.95)

Nsec = 7.1 turns ~ 7turns

What wire size should i use? Hope you can guide on this or at least give a better reference on this.

Thank you,